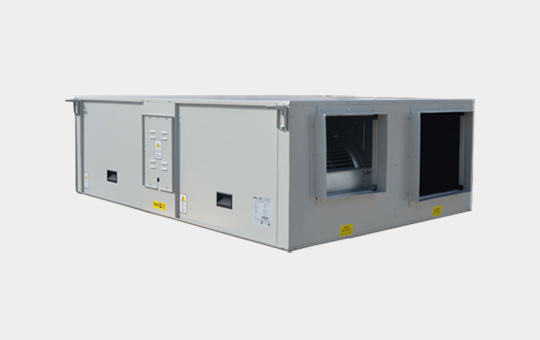

Heat recovery devices are also produced on CNC machines using galvanized alloyed static painted sheets. All internal surfaces of the devices are thermally and acoustically insulated. The devices are equipped with hangers for easy assembly. Polymer-based double-pass heat recovery exchangers are used in the units. By using 4 mm pitch in plate heat exchangers, more surface is obtained. Aspirator and ventilator fans are used as standard with 3-speed radial blades. Asynchronous electric motors strong enough to provide sufficient flow and pressure are used. Digital electronic control system is used in the devices. The blowing and suction flow rate can be adjusted separately on the wired remote control device. In models with electric heater, the heater can be used as 3 stages. The presence of inputs and outputs for Co2 sensor and in-duct temperature sensor and BMS enables to meet different needs.

Heat Recovery

What Does a Heat Recovery Device Do

Heat recovery devices allow people to create a cleaner and livable environment in their living spaces.

Heat recovery ventilation devices ensure that the exhaust air that needs to be discharged from the environment is discharged to the outside environment, as well as the fresh air required by the indoor environment via the same device. Heat recovery devices provide energy saving while performing ventilation function. While circulating fresh air and exhaust, it ensures that the energy of the heat-laden waste air is transferred to the raw fresh air. Heat recovery devices can work integrated with electric heater, water coil and DX battery. 3-speed radial fans are used as standard in heat recovery units. Today, the increasingly warming climate and the increase in energy inputs have made it necessary to use energy more effectively.

Heat Recovery Device Usage Areas

Heat recovery units are frequently used in heavily used environments such as offices, classrooms, cinemas, and theaters that require ventilation. In all heating and cooling environments, energy is saved by preventing the heat energy from being released with the help of the exhaust line. Heat recovery systems are indispensable in newly designed construction projects. In geographical regions where summer is very hot, cooling is an indispensable climate condition. If there is harmful gas and bad air in the cooled place, there is a need to exhaust from the environment. While the exhaust is done, the heat energy is also expelled. The use of heat recovery devices allows us to use less energy.

Advantages of Heat Recovery Units

In places such as cinemas and offices, there is sometimes a feeling of extreme cooling in winter. This is due to the air circulation from the interior to the outside. When the air is exhausted from the indoor environment quickly, sudden cooling occurs when cold air enters from the external environment instead of the air discharged from places such as doors and windows. Bringing in very cold outdoor air without being processed both disrupts the comfort conditions and means loss of energy. All of the standard aspirator devices create this effect. Only aspiration keeps the negativity. Making suction and blowing system with two separate aspirator devices also causes negative results. Heat recovery devices contain both aspirator and ventilator fans. Thanks to the cross-pass exchanger inside the device, heat and energy are recovered.